▶ 300 MerinoFine™ Polar base layer

Shop MerinoFine™Transparency

in every fibre.

Transparency in every fibre.

Supply chain partnerships

Natural fibre innovation

Regenerative farming

Transparency isn't a buzzword for us, it's woven into the very fabric of our brand.

Our commitment to transparency and visibility across our brand has guided us from day one, from open, honest communication about our materials to direct sourcing, we believe you deserve to know exactly how your gear comes to life, from fibre to finished product.

Our direct relationships provide full visibility across our production journey, from sheep to shirt. This enables us to implement responsible practices at each stage, identify improvement opportunities, and focus on accountability throughout our natural fibre ecosystem.

We actively seek out natural alternatives to synthetic materials, with the aim of reducing the need for petrochemical plastics in our performance gear. Our rigorous testing confirms that these natural solutions deliver measurable technical benefits while helping to eliminate unnecessary plastics from the products you rely on.

We prioritise and support regenerative farming principles and renewable resources across the merino stations we supply our wool from to help lighten our environmental footprint. Regenerative agriculture is a term that encompasses a variety of environmentally and socially conscious practices which aim to help promote biodiversity, enhance water cycles, improve soil health and sequester carbon.

DOWNLOAD 2024 TRANSPARENCY UPDATEMove to natural™

Move to natural™ is more than our vision, it's our commitment to embrace a more natural way of living. We invite you to join this movement and choose natural fibres over synthetics.

Our journey to

100% plastic-free

* fibre usage

Since embarking on our plastic-free journey in 2018, with 84% plastic-free fibre composition, we've made remarkable progress.

Today, 97.56% of fabrics in our 2024 collection are plastic-free—an achievement we're proud of, but it's a milestone rather than the destination.

Our commitment to creating performance apparel without unnecessary plastic remains stronger than ever.

*not including trims or decoration

80.75%

15.88%

0.85%

0.08%

2.44%

1.40%

0.50%

0.39%

Better wool, better products.

Our signature merino wool comes from select farmers who meet our rigorous standards for both fibre quality and environmental stewardship. While we remain deeply connected to our roots in New Zealand's heritage merino stations, growing demand has led us to carefully expand our sourcing to include select growers in South Africa and Australia.

We’ve partnered with The New Zealand Merino Company (NZM) and their ZQ certification programme which aims to ensure every farm—regardless of location—maintains the same standards for animal welfare, land management and fibre quality that define our products.

ZQ

93% of our merino wool is ZQ certified.*

The ZQ Merino standard represents the world’s leading ethical wool. Growers meet strict standards of animal welfare, environmental sustainability, fibre quality, traceability and social responsibility.

What it takes to be ZQ-Certified:

*Based on 2024 merino wool volumes

ZQRX Programme

79.98% of our wool is sourced from ZQRX farms*

ZQRX is a wool sourcing programme for ethical wool grown using regenerative farming principles. ZQRX growers work to improve farming practices, supporting the health of soil, biodiversity, carbon sequestration to minimise impacts on the environment and preserve the land for the future.

*Based on 2024 merino wool volumesDISCOVER MORE

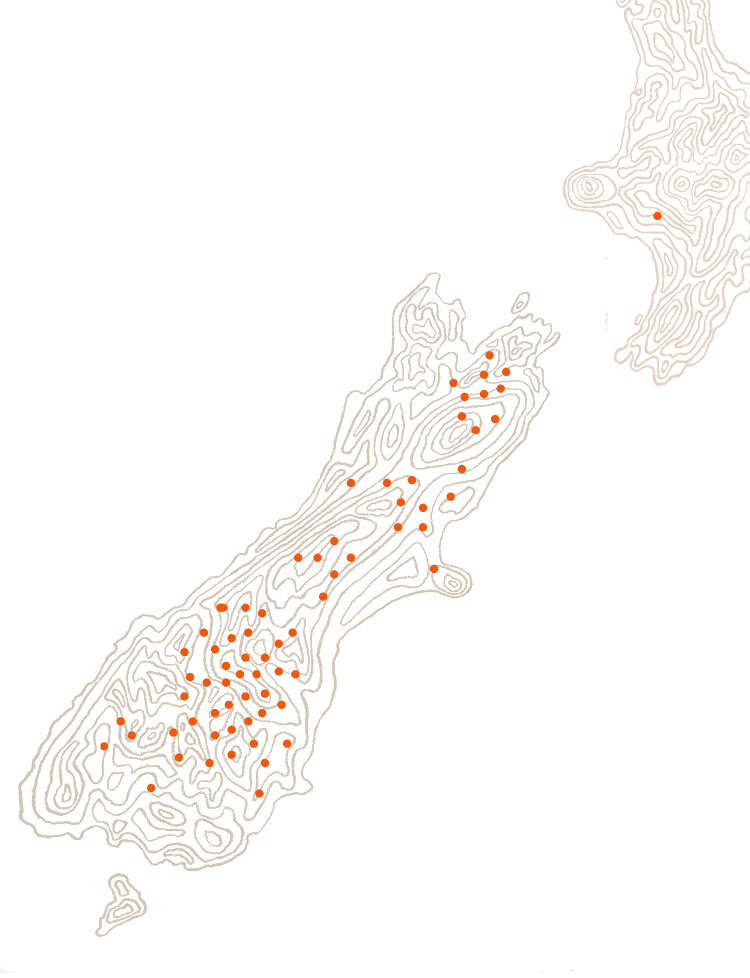

Pioneering the Growers Club

67 dedicated New Zealand stations are part of the Growers Club.

Pioneering the Growers Club

In 1997, we revolutionised industry standards by establishing the world's first long-term contracts with select merino growers.

Things evolved in 2018 when we partnered with The New Zealand Merino Company to create the 'Growers Club', unprecedented 10-year rolling contracts that provide security for farmers while ensuring consistent, merino wool fibres for our collections.

67 Growers

AWAPIRI

BENMORE STN HEART HEART

BLUE MOUNTAIN

BLUFF

BOG-ROY

CAIRNMUIR

CASTLE RIDGE

CORA LYNN

EREWHON

GLEN LYON

GLEN ORKNEY

GLENALLEN

GLENTANNER

GODLEY PEAKS

IDA VALLEY

LAKE HERON

LAKE OHAU

LINDIS PEAKS

MAHERUA

MATAKANUI

MIDDLEHURST

MT NICHOLAS

NOKOMAI

NORTHBURN

OMARAMA STATION

OTEKAIEKE

OTEMATATA

QUAILBURN DOWNS

WAITANGI

WALTER PEAK

ARDGOUR

BLACKSTONE HILL

BONJEDWARD

BRAEVAAR

CARRICK

CATHERINE FIELD

CECIL PEAK

CLAREVALE

CLUDEN

CORLEGGY

CRAGSIDE

CRAIGROY

DIP CREEK

DOLPHINS

EARNSCLEUGH

GLENFOYLE

GOULBURN

GRAMPIANS

GUIDE HILL

HARTFIELD

LAKE COLERIDGE STATION

LAKE TAYLOR

MANGAITI

MONAGHAN

MT MASON

MT ROSS

MT WHITNOW

MULLER

MUZZLE

PATEAROA STATION

REDCLIFFS STATION

RICHMOND BROOK

ROSENEATH

ROUGH RIDGE

STONEHENGE

THE GUMS

UPCOT

Relationships that matter.

As of 2024, we directly source 100% of our fabrics, 93% of our fibres and 93% of our trims. The remaining materials are sourced by our trusted fabric and garment partners, all adhering to our rigorous standards.

Air shipping remains our last resort, reserved only for exceptional circumstances beyond our control. Through careful forecasting and logistics management, we maintain sea and truck transport as our standard methods.

As of 2024, we directly source 100% of our fabrics, 93% of our fibres and 93% of our trims. The remaining materials are sourced by our trusted fabric and garment partners, all adhering to our rigorous standards.

Air shipping remains our last resort, reserved only for exceptional circumstances beyond our control. Through careful forecasting and logistics management, we maintain sea and truck transport as our standard methods.

From sheep to shirt

Our journey from raw fibre to finished product reflects our commitment to quality and transparency at every step.

Packaging

We're committed to sourcing packaging sustainably and working towards using more recycled packaging wherever we can.